000

"Glass is alive" this is the conception and perception of every glass craftsman. In Hamamatsu series of "Glass life", we focus on glass processing in this issue.

Beijing Hamamatsu Photon Techniques Inc. (BHP) has processing production line for large quantity products, including craftsman and automatic production line The capacity is more than 1 million pieces/year, including many kinds of glass products such as shells, stems, glass components etc.

1 Material treatment

In order to ensure air tightness of sealing parts, the glass and metal components need to be clear and pretreatment before processing. The sealed products can be deoxidized according to customer requirements.

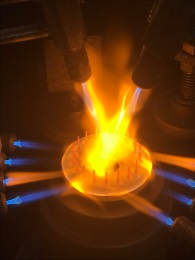

Fig.1 The process of kovar alloy

2 Setal welding

In addition to the glass-metal welding, we also have vacuum brazing and laser welding technology, that can weld various metallic components, and then seal with glass parts, in order to meet the needs of customers for complex products.

Fig. 2 Vacuum brazing

3 Sealing of glass

3.1 Sealing of shell

Manual/semi-automatic sealing equipment used to seal glass tubes and glass plates, can produce various types of glass shells.

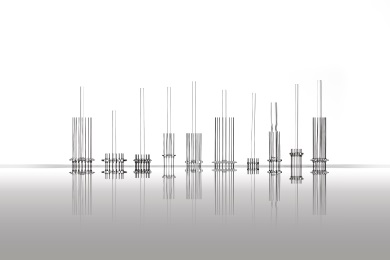

3.2 Pressing of glass stems

Manual/semi-automatic pressing equipment is used to form all kinds of plate glass stems.

Fig. 3 .Pressing of glass stem

Fig. 4 plate glass stem

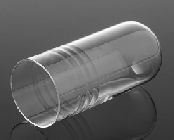

3.3 Glass grading transition sealing

BHP masters glass grading transition technology, which can seal the glass materials with different expansion coefficient from 5.5x10-7/℃ to 50x10-7/℃.

Fig. 5 transition technology of glass grading

Fig. 6 Silica glass and molybdenum group glass transition sealing products

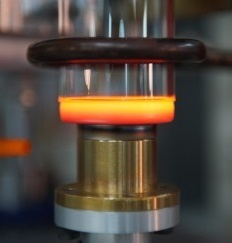

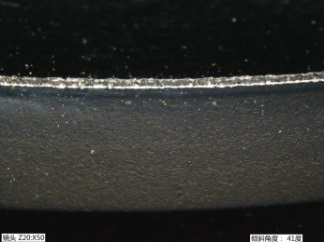

3.4 Glass-metal sealing

High-frequency heating or flame heating is used to seal the kovar alloy and glass. The sealed part has sufficient mechanical strength and thermal stability, also ensures air tightness. Fig. 8 shows a partial enlargement. The shape and size can be customized according to customer requirements. BHP is also focusing on new sealing technical exploration applied to the sealing between glass and oxygen-free Cu.

Fig. 7 glass sealing (left: high-frequancy sealing right: flame sealing)

Fig. 8 partial enlargement of sealed part

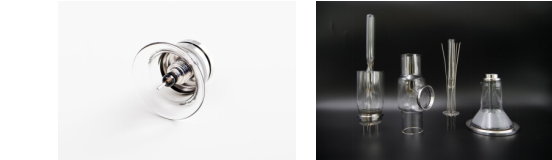

Fig. 9 products

3.5 Assembly

In order to meet the requirements of customers to simplify supply chain, BHP can provide more integrated glass products, such as stem assembly sealing plate glass stem with glass horn, and assembly sealing metal assembly with glass components, etc. BHP commits to provide integrated glass products solution for customers, with professional technology and experience to solve their worries, help customers focus on their own product development.

Fig. 10 Assembly product

4 Glass shaping

4.1 Glass shell shaping

For some glass shells that can not be blown into shape by the mold directly, it can be obtained by glass shaping technology. BHP can customize shape and dimension. At present, the maximum diameter of the product can achieve 200 mm.

Fig. 11 shaping of glass shell

4.2 Quartz glass process

The softening temperature of quartz glass is up to 1730℃, so the quartz glass processing uses hydrogen and oxygen flame(2500~3000℃). BHP has mature technology and production equipment for quartz glass, and specialized production lines.

Fig. 12 the shaping of silica glass shell

Fig. 13 Xenon lamp shell

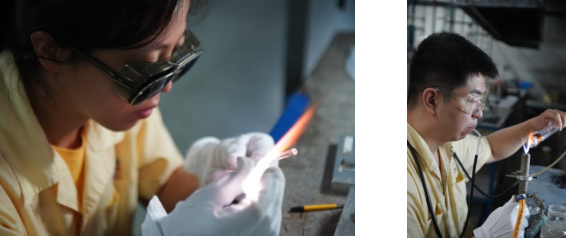

4.3 Manual forming

Manual forming uses Glass tube as the base material, utilizing the thermal properties of glass, with exquisite craftsmanship, completely relies on manual process, including bending, blowing, pulling, sealing, doing collar, turning, and other forming process.

Fig. 14 Manual molding

Fig. 15 Manual molding products

BHP is committed to electric vacuum glass manufacturing for many years and have rich experience in research and development, strong technicians and strict quality control, and always challenge the industry "bottlenecks" problem, committed to providing all kinds of complex structure of glass solution, do a good job with every product with the spirit of craftsmanship.

BHP concentrates on electric vacuum glass materials and manufacturing for more than 20 years, accumulates many experiences in research and development, technical process and quality control methods, challenges the "bottleneck" problems in electric vacuum glass field, keeps on improving our ability to provide glass products solution to implement the customer's designs.