000

“Glass is alive”, this is the conception and perception of every glass craftsman. In the series of “Glass life”. Let us start from glass forming in this part.

Glass forming is a process that transforms molten state glass into fixed geometry state. This process is the result of complex combination of many different properties actions, among them, mechanical and thermal actions are most significant. The process of forming can be divided into two stages, i.e. modeling stage and shaping stage. Modeling stage defines the shape, shaping stage solidifies it. These two stages both are related to the glass viscosity, because molten glass can have any desired viscosity, the glass material has different forming methods. It can be divided into the following types roughly:

Pressing method: inject molten glass into a given model, place die ring, press the plunger chip, then form products .

Blowing method: blow molten glass in a model through blowing tube or blowing head. This method is divided into manual blowing and mechanical blowing.

Pulling method: blow molten glass in a model through blowing tube or in mechanical equipment, cooling, then pull according to the requirements.

Calendering method: calender molten glass into forming products through rollers or roller plates.

Casting method: inject molten glass into a mold to forming products after annealing and cooling.

Float forming: this is a special method to form flat glass, molten glass flows into a tin tank, and a flat can be formed on the surface of molten tin

The main glass forming techniques are as follows:

manual blowing:

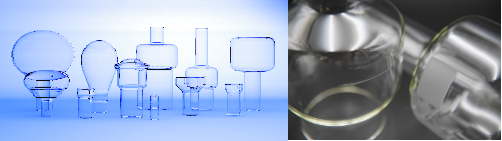

we can blow spherical, circular, square, six-prism glass shell products according to the customer’s requirements

Fig. 1 Manual blowing

The product sample glass shell

Fig. 2 Glass shell products

2 manual pulling

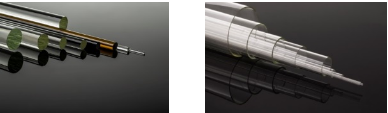

According to customer requirements, we can produce glass tube and rod with different materials and specifications.

Fig. 3 Manual pulling

The product sample glass rods and glass tube

Fig. 4 Glass tube and rod products

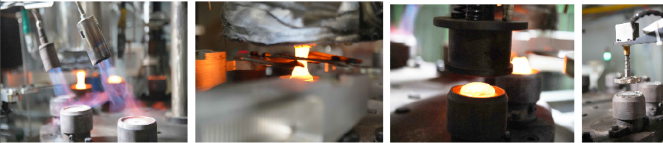

3 Automatic calendering:

Automatic pressing equipment can press a variety of shapes of the plate.

Fig. 5 Automatic pressing

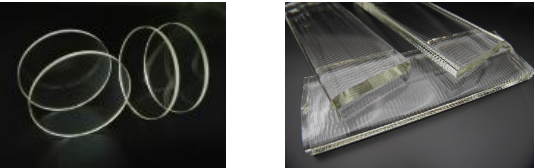

The product sample plates and sheets

Fig.6 A variety of shapes of the plate

BHP concentrates on electric vacuum glass manufacturing for more than 20years,accumulates many experience in research and development, strong technicians and strict quality control, and always challenge the industry “bottlenecks” problem, committed to providing all kinds of complex structure of glass solution, at present BHP is committed to full-time porcelain platinum even melting electric furnace automatic control and automatic blowing technology research. We will escort China’s intelligent manufacturing transformation with the spirit of craftsmanship.

BHP concentrates on electric vacuum glass materials and manufacturing for more than 20 years, accumulates many experiences in research and development, has a strong team of technicians and quality control methods, always challenges the “strangle” problems in electric vacuum glass field, keeps on improving our ability to provide glass products solution to implement the customer’s designs.