000

“Glass is alive.” This is the idea and understanding of every glass craftsman. In the series of “Glass Life”, of BHP Forum, let us start with Glass Melting Technology to learn about glass---an ancient civilization that originated 5,000 years ago.

“Glass is alive.” This is the conception and perception of every glass craftsman. In the series of “Glass Life”, of Hamamatsu Forum, let us start learning this ancient civilization 5000 years ago from Glass Melting Technology.

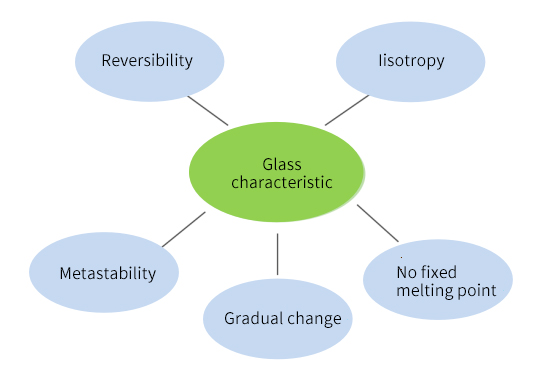

On books, glass is defined as "an amorphous solid that exhibits complete structural long range disorder and possesses glassy properties". Compared with our familiar daily glass, the glass produced by Beijing Hamamatsu Photon Techniques Inc. (BHP) belongs to electric vacuum glass. Because of its high softening temperature, good electrical insulation performance, lower conductivity and dielectric loss, it is widely used in vacuum electronics technology, microelectronics, laser and infrared technology, electric light source, high energy physics, etc. In the category of electric vacuum glass, according to the glass composition, BHP’s glass belongs to borosilicate glass; according to the coefficient of thermal expansion, it belongs to molybdenum group glass, that can achieve good sealing with kovar alloy (4J29).

The process of glass melting is a series of physical, chemical and physicochemical changes, a process that various raw materials mechanical mixture transforms into a complex molten material, i.e. glass. as shown in following table:

Physical change | Chemical change | Physicochemical change |

The compound material is heated up | Solid phase reaction | Formation of eutectic |

Compound dehydration | Decomposition of carbonate, sulfate and nitrate | The dissolution of a solid and intermelting of a liquid |

Melting of components | Decomposition of hydrates | The interaction between liquid glass, furnace gas and bubbles |

Crystal phase transition | Decomposition of chemically bound water | The interaction between liquid glass and refractory material |

Volatilization of individual components | Formation and interaction of silicates | —— |

BHP uses two glass melting methods:

1) Crucible furnace method

This method can meet the requirements of multi-varieties, small batches, for research and development experiments.

2) Electric furnace method

In 2020, a full-time porcelain and platinum electric melting furnace was completed and put into production. it can meet the requirement of stable mass production. The melting temperature can be as high as 1600℃, can obtain better glass material than crucible furnace, that can be widely used in photomultiplier tube, X-ray tube and other electric vacuum products. Currently, the mainly product is CG294(similar to Schott 8245).

In addition, BHP also customize glass materials according to customer requirements, mainly used in micro channel plate and optical fiber panel products.

Crucible furnace Electric furnace

Since defects of glass, such as bubbles, stones, stripes and so on, are mostly caused during melting process, it is very important to analyze a reasonable process and establish a reasonable melting system. It can also be said that glass melting process is the origin of glass life, is the leader of entire glass production line.

BHP keeps on developing and applying new processes and technologies, in order to meet the increasing product requirements of customers.