000

"Glass is alive", which is the voice and feeling of every glass craftsman. The "Glass Life" series pushes the applications of focused glass products in this issue. The vacuum glass products produced by BHP mainly include: Various glass tubes, rods and glass shell products directly produced by manual drawing and blowing process, as well as glass shells and glass core column products for photoelectric devices manufactured by secondary molding of glass blowers, including: "matching or non-matching sealing products between borosilicate glass and glass or metal", "quartz glass products", and "handmade glass products" of various sizes and shapes. Let's see where these forms of glass products can be used.

Fig. 1 Crucible furnace (left) and self-designed and built full-time porcelain platinum continuous-melting electric furnace (right)

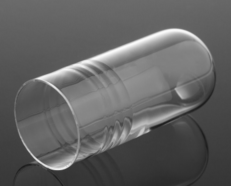

The glass melting system of BHP is divided into crucible furnace and self-designed and built full-time porcelain platinum continuous-melting electric furnace (Fig. 1). Both have their respective advantages and complement each other. Various glass tubes (Fig. 2), rods, glass shells (Fig. 3) and plates (Fig. 4) and other electric vacuum glass products are widely used in the PMT shells, X-ray tube glass shells, special glass and other glass products.

Fig. 2 Glass Tubes Fig. 3 Glass Shells Fig. 4 Glass Plates

The glass graded transition technology of BHP can realize the sealing of glass with the expansion coefficient α transition from 5.5×10-7/℃to 50×10-7/℃ (Fig. 5). The products are mainly used for various electric light source tubes.

Fig. 5 Glass Graded Transition Tubes

The glass-to-glass sealed product, used as a glass shell (Fig. 6) is used for various types of the PMTs and hollow cathode lamps (Fig. 7).

Fig. 6 Glass Shells Fig. 7 Photomultiplier Tube (left) and hollow cathode lamps (right)

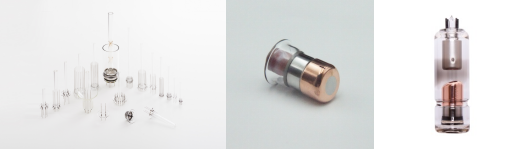

Glass-metal sealing product (Fig. 8), as a shell or internal fitting, is used for various types of X-ray tubes and their components (Fig. 9).

Fig. 8 Glass-metal sealing product

((Extracted from Siemens website)

Fig. 9 X-ray tubes and their components

Various models of plate mandrel pressing and anode assembly fabrication (Fig. 10) are used as glass mandrels and assemblies for various types of the PMTs and X-ray tubes (Fig. 11).

Fig. 10 Plate mandrels (left) and anode assemblies (right) Fig. 11 X-ray tubes

Quartz glass products and hand-made glass products (Fig. 12) are used as glass housings for various xenon lamp light sources (Fig. 13), various tools or components for vacuum electric device processing, such as glass fireheads, glass holders for exhausting electron tubes, etc.

Fig. 12 Quartz glass products Fig. 13 Xenon lamps

After high-temperature melting, white quartz sand gradually turns into crystal and clear glass liquid, flowing, reorganizing and changing silently. It is endowed with new interpretation by glass craftsmen with eyes, hands and soul, leading people to create infinite possibilities. The glass manufacturing technique is the painstaking inheritance of "craftsman's spirit" and the eternal pursuit of "ingenuity". Here, let's experience the collision of "spirit" and "technique" together, and lament the transformation and sublimation behind ordinary people.