000

“Glass is alive”, which is the voice and feeling of every glass craftsman. With the development of the times and the progress of society, many new technologies and new processes have emerged in glass production, mechanized and automatic equipment replacing manual blowing came into being.

Fig. 1 Full-time Drawn Glass Tubes

Tube drawing machine is a general mechanical device for glass tubes forming, and also an important device for continuous forming glass tubes. It has the advantages of high output, stable quality, high finished product rate and easy changing glass tubes specifications. There are many methods for forming glass tubes by machine, and the main methods are as follows: horizontal drawing method, vertical drawing-up method, vertical drawing-down method and spinning method.

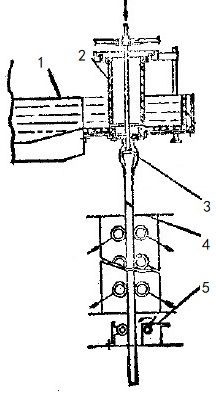

1- Material channel, 2- Homogenizer, 3- End, 4- Tractor, 5- Mechanical tube cutting

Fig. 2 Vertical drawing-down molding

At present, the BHP adopts vertical drawing-down method (Fig. 2), which can draw both large-diameter thick-wall tube and small-diameter thin-wall pipe. The operating principle is as follows: The powder is added into the main furnace for melting, filtered through 1-material channel, stirred to remove bubbles and streaks, then flows into 2-homogenizer of the tube drawing unit. By controlling the temperature and the speed of the 4-tractor, changing the distance between the 3-end and the discharge port, adjusting the blowing volume, etc., the outer diameter and wall thickness of the drawn glass tubes can be stably controlled. Through constant experiment and groping, the BHP has mastered relatively perfect technology. The drawing diameter can be controlled within 4mm-30mm, the wall thickness can be adjusted within 0.6mm-2.0mm, and the wall thickness deviation is controlled within 0.2mm.

BHP has an annual production of 60 tons of glass tubes, glass rod materials, 500,000 glass shells and 1,000,000 pieces of professional glass products, mainly used in various high-quality electric vacuum products. Deeply engaged in the production and manufacture of electronic glass and its products for more than twenty (20) years, the BHP has a young team with rich experience and strong innovation ability. It has always been committed to challenging the problem of “stuck neck” in the industry, and is committed to providing customers with various solutions for glass products with complex structure, inheriting the spirit of craftsmen and making each product with care.