000

The knowledge about the properties, classifications and applications of scintillators is described earlier, mainly based on the properties of scintillators that convert high-energy particles into visible light. In the process of transforming scintillators from blanks to products, corresponding processing and surface treatment shall be carried out according to the physical properties of scintillators. The following is about “Processing of scintillator”.

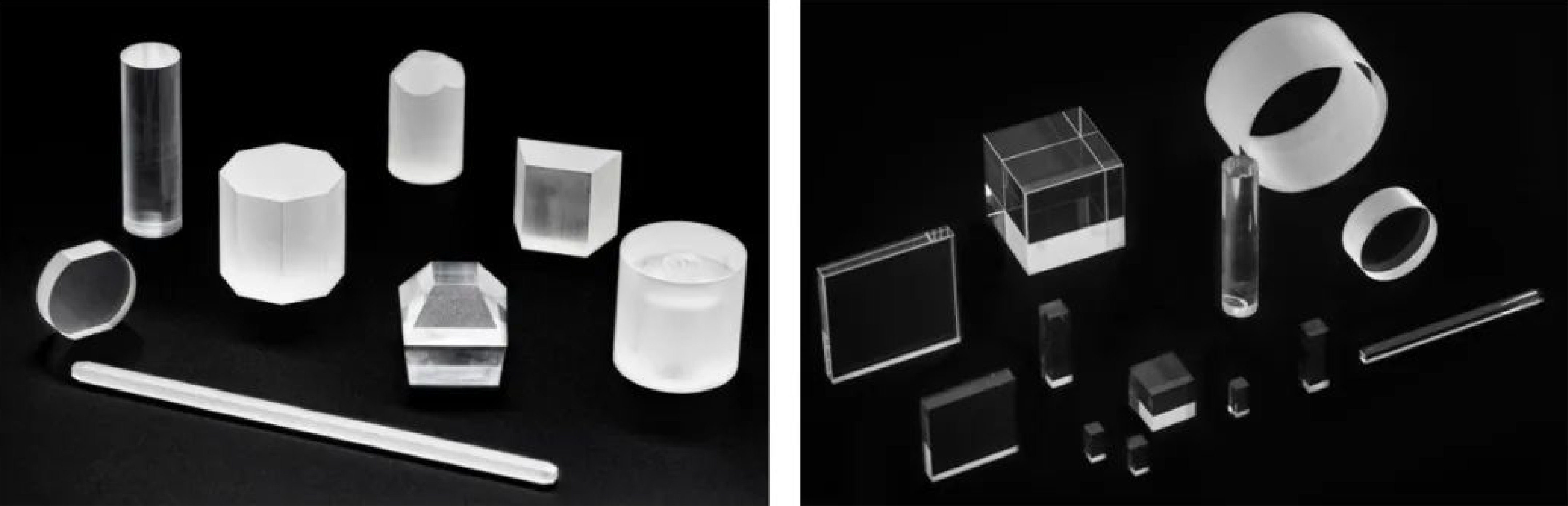

Different from traditional machining methods such as lathing, milling, planing, grinding, etc., the processing of a scintillator mainly consists of band saw cutting, inner circular cutting, outer circular scribing, diamond wire cutting, etc., supplemented by other processing methods (lathing, milling, grinding and polishing, etc.) (Fig.s 1 and 2).

Fig. 1 Cesium iodide products Fig. 2 Yttrium lutetium silicate products

Fig. 1 Cesium iodide products Fig. 2 Yttrium lutetium silicate products

The processability of different scintillators is different except the performance indicators.The following describes the processing characteristics of several BHP scintillator materials:

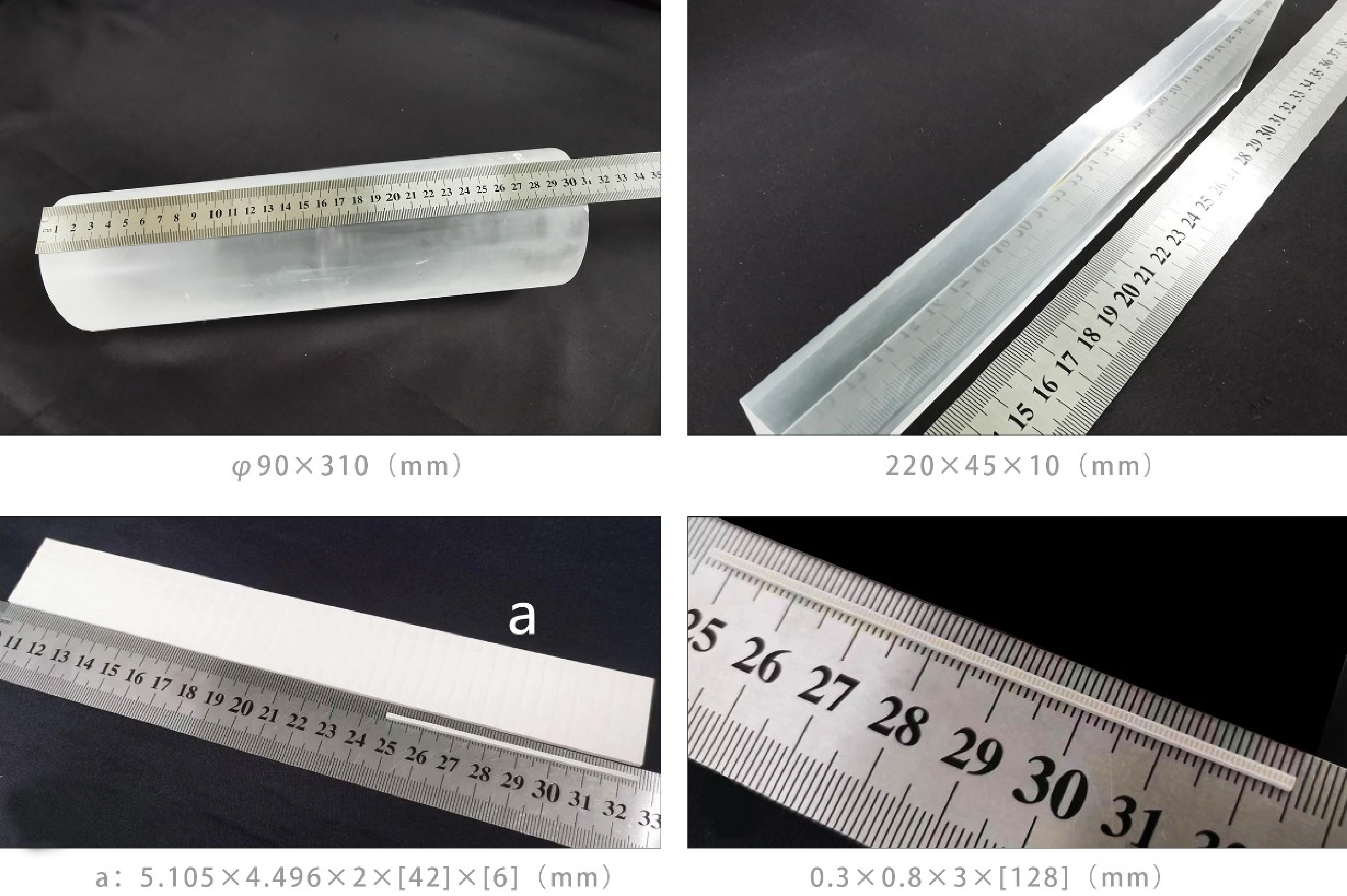

Cesium iodide scintillators (CsI) (Fig. 3): Slightly deliquescent, low hardness (Moh’s hardness 2), easy to produce deformation during processing;

Fig. 3 Example of CsI scintillators

Fig. 3 Example of CsI scintillators

(The number in [ ] is the X or Y pixel number of the array product, the same below)

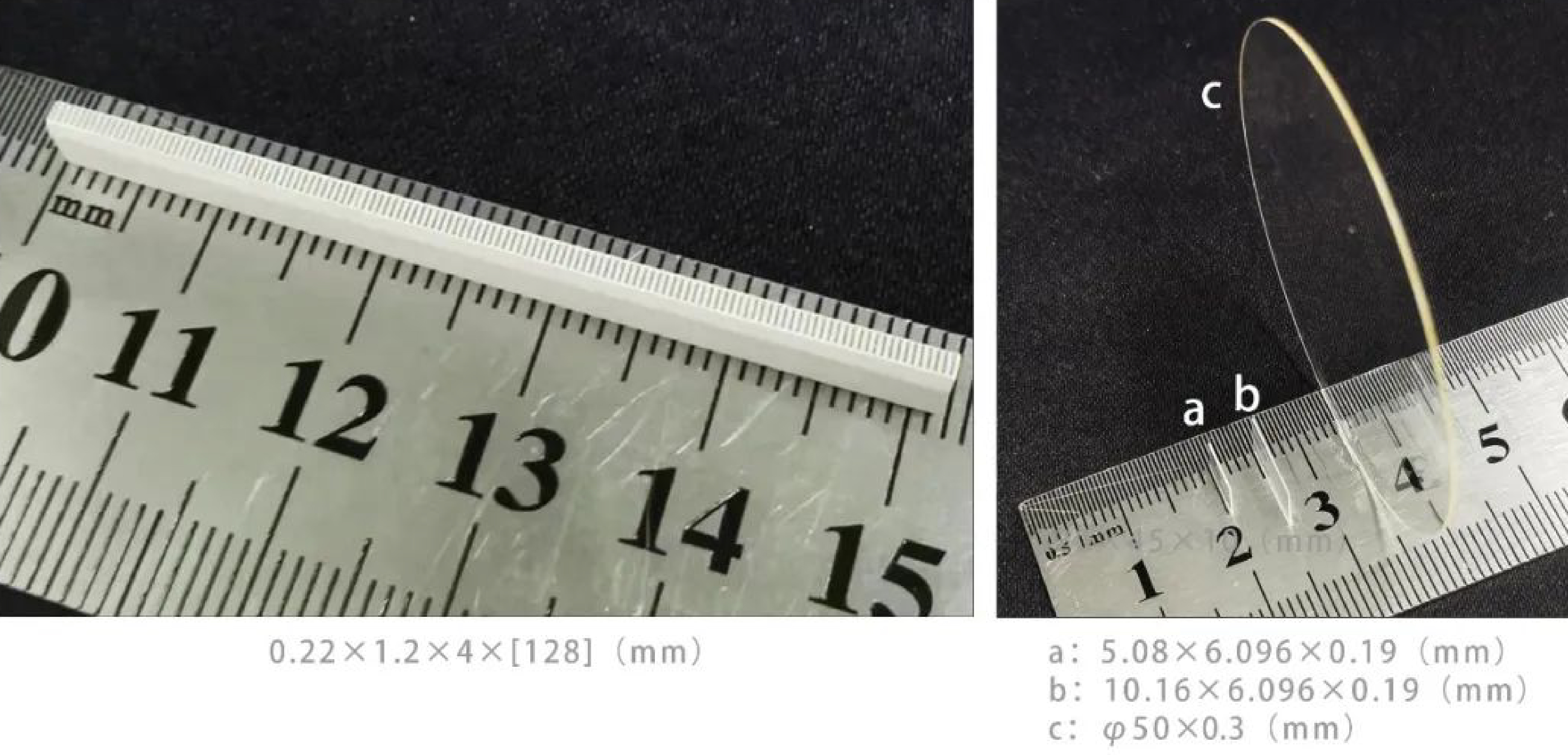

Cadmium tungstate scintillator (CWO) (Fig. 4): No deliquescence, moderate hardness (Moh’s hardness 4-4.5), easy to cleavage during processing;

Fig. 4 Example of CWO scintillators

Fig. 4 Example of CWO scintillators

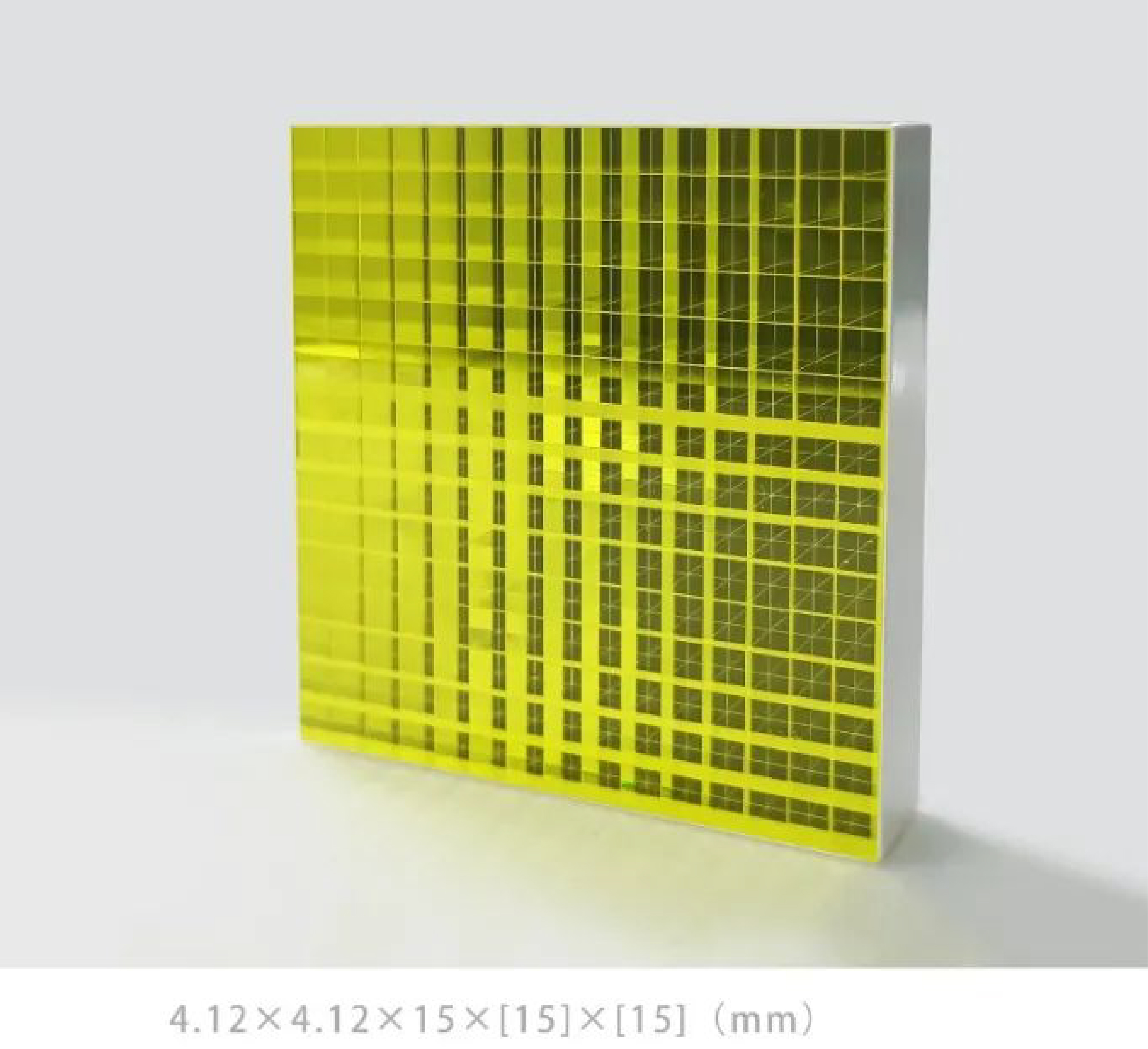

Rare earth garnet-based scintillator (RGBS) (Fig. 5): No deliquescence, large hardness (Moh’s hardness 8), large tool loses and easy to crack during processing;

Fig. 5 Example of RGBS scintillators

Fig. 5 Example of RGBS scintillators

Each scintillator material has its own characteristics, which needs to be fully considered and utilized during processing to achieve efficient mass production. For the scintillator materials mentioned above, during processing and manufacturing, besides taking into account the factors such as the material’s own deliquescence, cleavability, Moh’s hardness and whether it is easy to crack, etc., it is also necessary to consider the influence of various external environmental factors, such as bonding conditions and cleaning conditions, so as to formulate a processing method more consistent with the scintillator. At present, our cesium iodide products can meet the processing requirements of complex and irregular shapes such as multi-angle, deep aperture, etc. Meanwhile, the processing size can reach 0.1mm~500mm. The RGBS scintillator can achieve nano-level polishing.

BHP has been engaged in the research, development and production of scintillator -related products for nearly 20 years. It has a complete set of product processing lines, hundreds of devices and a manufacturing team with rich experience in processing, which can meet the customization needs of different customers.