000

1. Borosilicate glass

Compared with ordinary glass, borosilicate glass is a kind of glass material with high heat resistance, high chemical stability and high mechanical properties, containing about 13% boron oxide. In the fields of electronic packaging metal shells, relays, solar vacuum tubes, etc., it is necessary to use the matching sealing products of kovar alloy and borosilicate glass (see Fig. 1). The quality of the sealing between kovar alloy and borosilicate glass largely depends on the wetting behavior of the molten glass on the oxide film on the surface of kovar alloy under high temperature conditions, so the wettability is an important condition for the good bonding between borosilicate glass and kovar alloy, and directly affects the interface bonding strength between borosilicate glass and kovar alloy.

Fig. 1 Matching sealing products of kovar alloy and borosilicate glass

2. Wettability

Borosilicate glass is a kind of material with good wettability. So what is wettability?

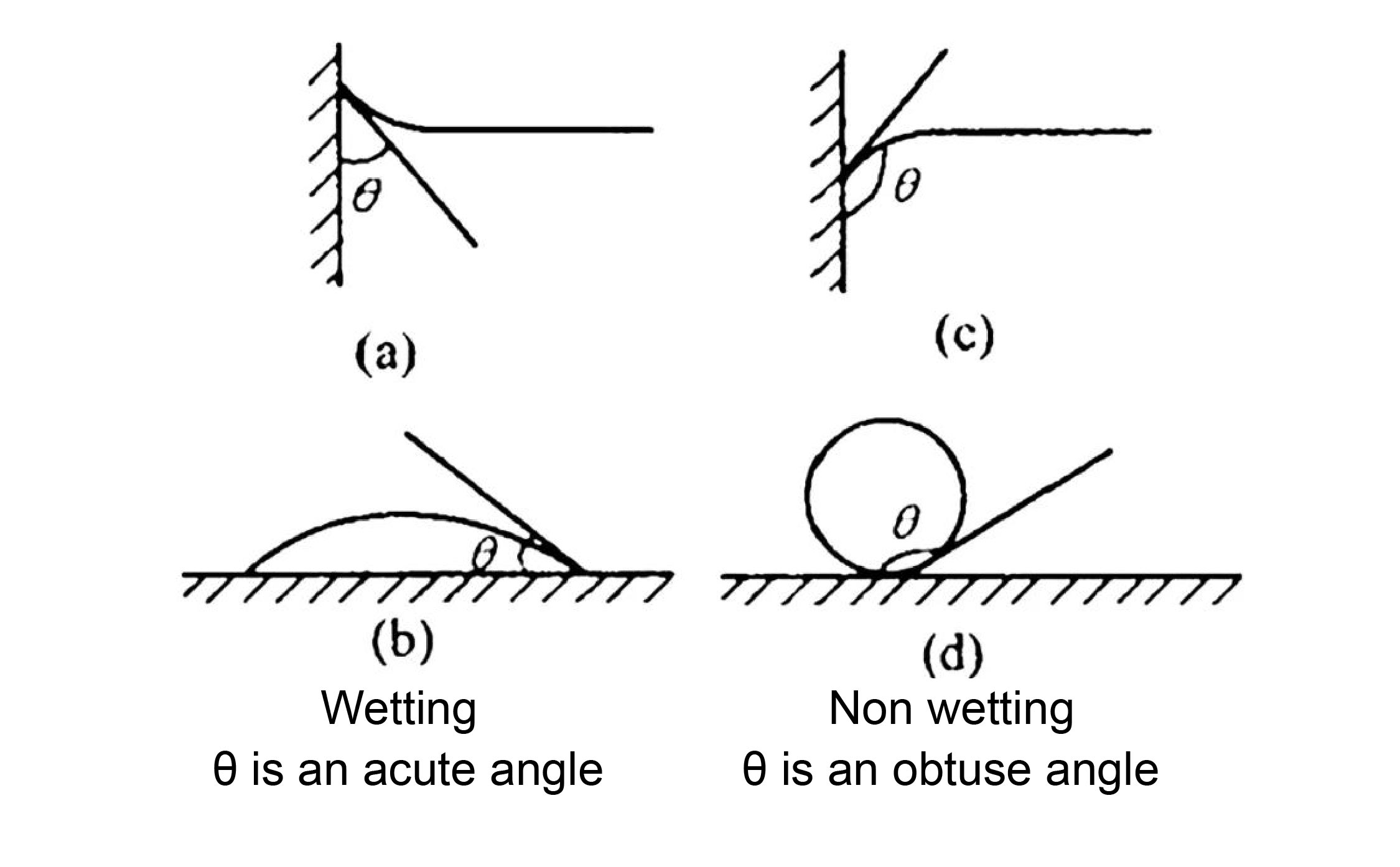

The wettability of a solid is determined by the wetting angle, which is the angle between the tangential line of the liquid drop at the solid-liquid contact edge and the solid plane. When a liquid drops on a solid surface, its wettability may vary as indicated by this θ angle.

The wetting θ angle ranges from 0° to 180°. The lower the wetting angle, the higher the wettability ( Fig. 2).

When θ=0, the liquid exhibits complete wetting of the solid surface. The liquid demonstrates spreading behavior on the solid surface.

0 < θ < 90°, the liquid can wet the solid, and the smaller the θ, the better the wettability.

90° < θ < 180°, the liquid cannot wet the solid.

θ=180°, the two are not wet at all, and the liquid condenses into small balls on the solid surface.

Fig. 2 Wetting angle diagram

Note: Fig. 2 is taken from Baidu Encyclopedia

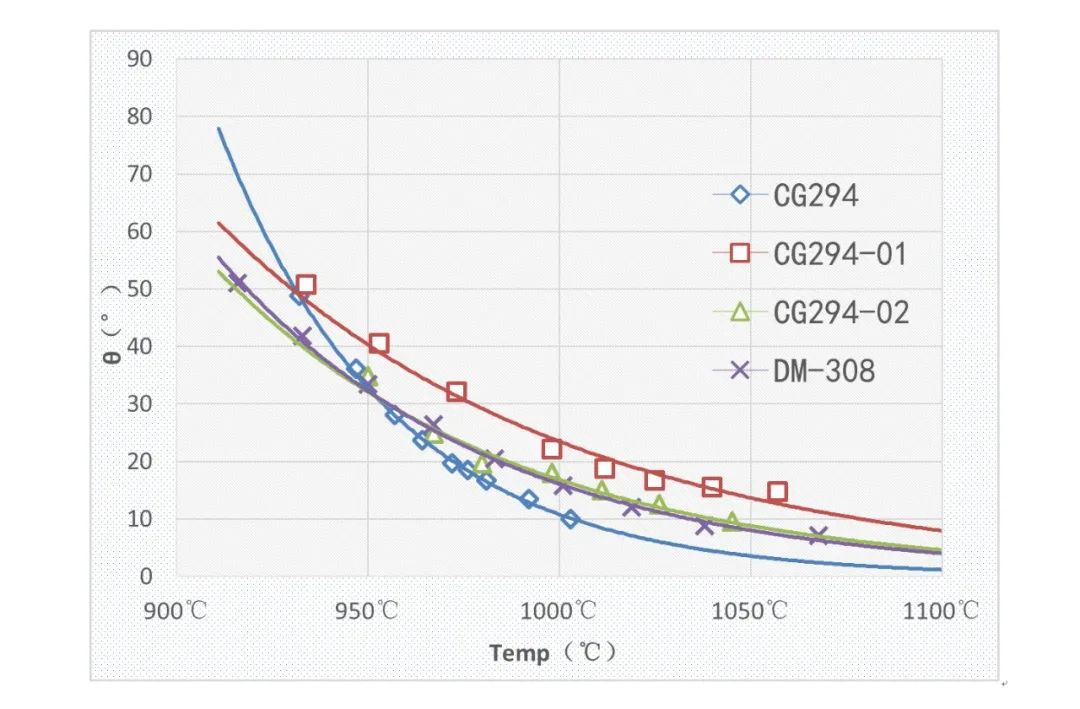

Wettability problems are often encountered in the sealing process of kovar alloy and glass. Whether glass and kovar alloy sealing is dense or not depends on the wetting condition of glass to kovar alloy, the better the wetting condition, the smaller the wetting Angle, the better the mutual adhesion force between kovar alloy and glass, the more dense the sealing. The wettability relationship between Beijing Hamamatsu borosilicate glass and kovar alloy is shown in Fig. 3.

Fig. 3 Wettability relationship between borosilicate glass and kovar alloy

On the whole, the performance of CG294 is better than that of DM-308, CG294-02 and CG294-01 at high temperature sealing (950℃). The kovar alloy and borosilicate glass matching sealing products produced by Beijing Hamamatsu have sufficient mechanical strength and thermal stability to ensure air tightness, and are widely used in various types of X-ray glass shells, and the shape and size can be customized according to customer needs.

In addition, on the basis of traditional glass melting and manual forming processing, Beijing Hamamatsu has successively introduced many advanced production devices and processing technologies at home and abroad, set up a large-scale glass production line. can produce electronic glass materials and products with small batch, multi varieties and high precision according to the requirements of customers, and also provide incoming materials processing services.

Fig.4 Production of glass stems

Beijing Hamamatsu Photon Techniques INC. has been deeply engaged in the manufacture of electronic glass and its products for more than twenty years. We have a young team with rich experience and strong innovation ability. We are always committed to challenging the problem of “Stuck Neck” in the industry, and providing customers various solutions for complex structure glass products, inheriting the spirit of craftsmen and making each product with care.