000

Glass can be made into a variety of shapes and can be sealed with metals because of its excellent insulation performance. As a result, glass is one of the main materials for airtight sealing between the bulb and the straight lead. Borosilicate glass and kovar alloy are extensively applied. The expansion coefficients of the two are very similar, therefore, matched sealing can be achieved. Such product is widely applied in all kinds of photoelectric devices like photomultiplier tubes and X-ray tubes.

Fig.1 Metal-glass sealing products

Fig.2 Glass stems

The glass-kovar alloy sealing mainly falls into three steps: hydrogen burning, pre-oxidation, and heat sealing:

① Hydrogen burning of kovar alloy

The hydrogen burning treatment offers a good basis for the formation of oxide layer on surface (see Fig. 3). If there are oil stains, impurities, gases and other pollutants on the metal surface, a great number of bubbles will occur at the sealing point upon sealing, which will result in gas leakage and explosion and affect airtightness, mechanical strength, electrical energy and other indicators. The hydrogen burning essentially means the annealing of Kovar alloy parts in a hydrogen furnace. In the whole annealing process, the heating, thermal insulation, and cooling of the parts are performed under the protection of hydrogen flow. Hydrogen not only prevents the surface of Kovar alloy parts from being oxidized during heating, but also deoxidizes the metal oxide on the surface of the parts;

Fig.3 The hydrogen burning treatment

Meanwhile, a small amount of water contained in hydrogen can be decomposed into oxygen at high temperatures, which is beneficial to decarburization on the surface of metal materials and is quite effective in surface purification. Throughout the thermal treatment of heating, thermal insulation, and cooling, the internal grains of Kovar alloy parts complete recovery, recrystallization, and grain growth. In this manner, the stress on the parts will be fully eliminated and balanced, to ensure the steady linear expansion coefficient during Kovar alloy sealing.

② Pre-oxidation treatment of kovar alloy

The chemical bond of kovar alloy is a metal bond, while that of glass is an ion-covalent bond. Therefore, kovar alloy and glass cannot be directly sealed. The kovar alloy needs to undergo pre-oxidization before sealing (see Fig. 4) to form a layer of oxide film on alloy surface, through which kovar alloy can be sealed with glass. As a matter of fact, the oxide film is fused with glass. The reliability of sealing largely relies on the metal oxide film with the thickness controlled within a certain range. If the oxide film is too thin, it will be completely melted in the glass. As a result, the glass and the metal substrate surface are directly sealed, causing a reduction in sealing strength; If the oxide film is too thick, a rough and loose oxide film will remain on the metal surface, as a result, air leakage occur to the sealing part.

Fig.4 Pre-oxidation treatment

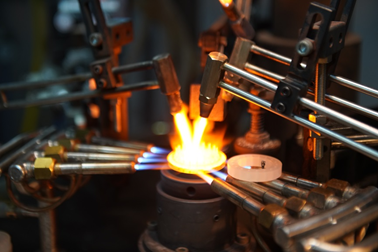

③ Heat sealing of glass and kovar alloy

When the glass reaches a molten state by heating, the metal oxide formed can firmly adhere to the metal surface and dissolve into the molten glass. A transitional layer of compositional gradation is formed between the metal oxide layer and the glass, and it tightly bonds the glass and metal oxide layer together, to achieve the sealing of glass and kovar alloy.

Fig.5 Heat sealing of glass and kovar alloy

Beijing Hamamatsu possesses a complete glass production line, produces a variety of glass tubes, rods, and glass bulb products by using drawing and blowing processes, and manufactures glass bulbs and glass core columns for photoelectric devices by means of scientific glassblowing and secondary molding processing (like flame or induction sealing).

Beijing Hamamatsu Photon Techniques INC. has been thoroughly engaged in the production and manufacturing of electronic glass and its products for years, and possesses an experienced and innovative young team. We are not only always devoted to addressing the Bottleneck problem in the industry, and offering customers with solutions for glass products with complicated structures, but also committed to inheriting the artisan spirit, and wholeheartedly making every product.